- Very large to very small containers recycled

- Contaminated plastics hot-washed prior to shredding

- Redundant fuel tanks accepted

- Bulk loads accepted and collected

- Significant 2020 process equipment upgrades

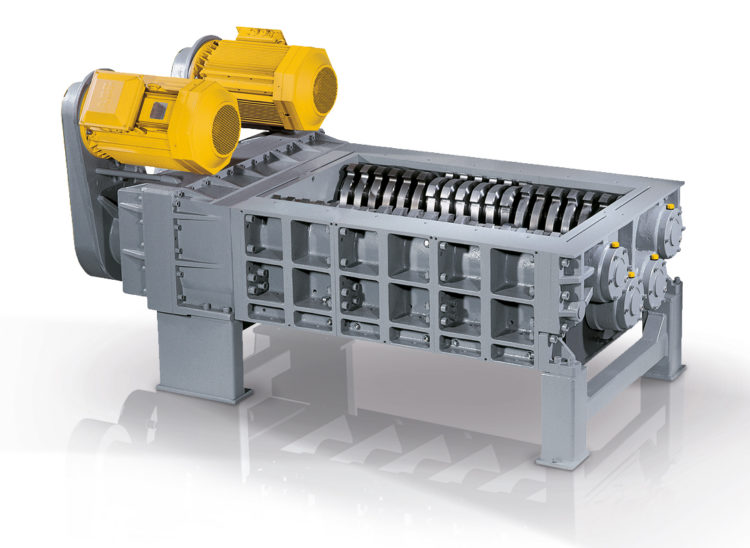

Now equipped with brand new shredding and handling machinery, we have further increased both the throughput and container size range of our process.

We operate a fully integrated plastic recycling plant capable of processing contaminated or clean material from a wide range of producers. We regularly accepts pallet boxes, IBCs , wheelie bins and similar items. Non-plastic elements such as metal frames are recovered and sent off site for smelting.

The continuous shredding, washing, drying and granulation process means that we can recover both containers and contents which would otherwise go to landfill or for incineration.

The non-biodegradable nature of most plastics, together with their widespread use, means that they continue to represent a major problem for the environment. By shredding and recycling such plastics for use as fresh feedstock or other purposes, we not only avert the disposal option but reduce the requirement for oil from which most plastics are made.

Photo 3 courtesy of UNTHA (UK) Ltd